RBI Hawker

RBI Hawker Limited, a Joint Venture between Hawker Pacific Airservices Ltd and Bell, commenced operations in 2005 with a hand-picked team of specialised rotor blade repair professionals.

By establishing two world class Helicopter Rotor Blade Repair and Overhaul Facilities in strategic locations in the Middle East (Corporate Headquarters) and Australia, we can service the needs of both commercial and military helicopter operators in Africa, Asia, Oceania, Eastern Europe and the Middle East.

Our state-of-the-art facilities in the Jebal Ali Free Zone in Dubai and Brisbane, Australia have been strategically chosen due to their central locations and ease of access to transportation links by sea, air and road. These key elements are crucial to ensuring we can transport blades door-to-door anywhere in the region, resulting in a reduction in costs and time.

Each 1,000 square metre, air-conditioned facility features:

- Climate controlled (temperature and humidity) bonding and balance areas.

- Segregated inspection and repair areas.

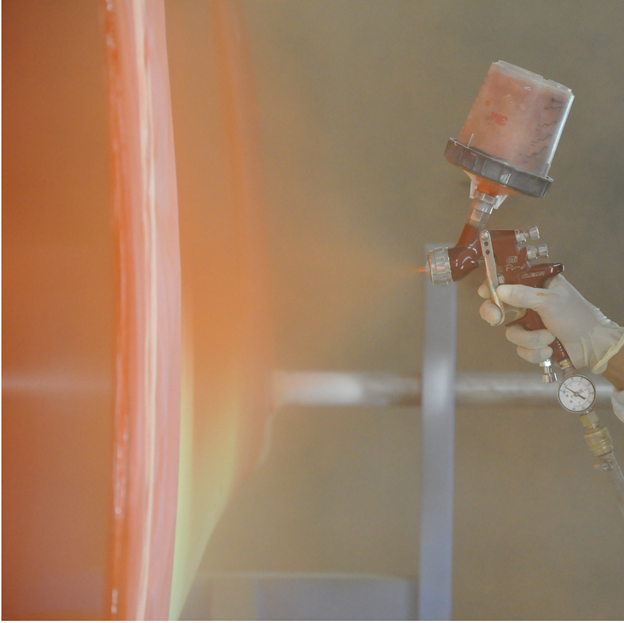

- Specific spray paint booth.

- Advanced electronic balancing system.